Automated material handling

The variety of driverless vehicles (AGVs) and automated material handling systems have expanded tremendously over the years. Following industrial application the use of autonomous material handlers have first reached the warehousing industry, then human servicing areas. Their size and design vary depending on the area of application.

Main types:

- open track material handlers, milk-run

-

automated unit load transporters such as

- automated forklift

- platform AGV

- AGV with forklift functions

- automated vehicles

Open track automated material handling equipment, milk-run

Open-track automated material handling equipment is now a common, widespread means of material supply within the supply chain. It is typically used to supply production lines and production islands. These types of AGVs are used to collect finished goods from production. However, due to their towing ability, they can also be used for other specific tasks, like long distance material handling, as a trailer.

The system is also suitable for in-site and inter-site material handling. The key feature of their operation is that they distribute and collect goods on a single line, within a given time window. The starting and end points of the operation are usually the same (start from the warehouse, travel through the site, then back to the warehouse). Open track AGVs are usually used on a route-by-schedule basis. Milk-run systems are typically used with a driver, for the automated material handling of large quantities of continuously produced goods. Automation in this case is primarily manifested in the towed cargo’s automation. Nowadays, however, the milk-run AGV system is also spreading as a fully automated solution. When setting up AGV servers it is also required to develop the AGV control software, and thus defining the servers’ operational theory and method, basic process changes, occupational safety inspection methods and frequency and the relevant policies also have to be issued.

The system is also suitable for in-site and inter-site material handling. The key feature of their operation is that they distribute and collect goods on a single line, within a given time window. The starting and end points of the operation are usually the same (start from the warehouse, travel through the site, then back to the warehouse). Open track AGVs are usually used on a route-by-schedule basis. Milk-run systems are typically used with a driver, for the automated material handling of large quantities of continuously produced goods. Automation in this case is primarily manifested in the towed cargo’s automation. Nowadays, however, the milk-run AGV system is also spreading as a fully automated solution. When setting up AGV servers it is also required to develop the AGV control software, and thus defining the servers’ operational theory and method, basic process changes, occupational safety inspection methods and frequency and the relevant policies also have to be issued.

Automated unit load transport equipment

Automated unit load transport equipment is a very versatile machine type, used in both manufacturing and logistics. Countless bodywork types can be purchased and designed for base AGV platforms, with which the AGVs can be improved for a specific task. The AGV server, that controls the equipment, is a complex software that optimizes traffic routes based on traffic intensity, intersections along the route, as well as nodes based on the number of loading and unloading points, and the level of priorities in traffic. The AGV server software is usually an integral part of MFC, the automated material flow control.

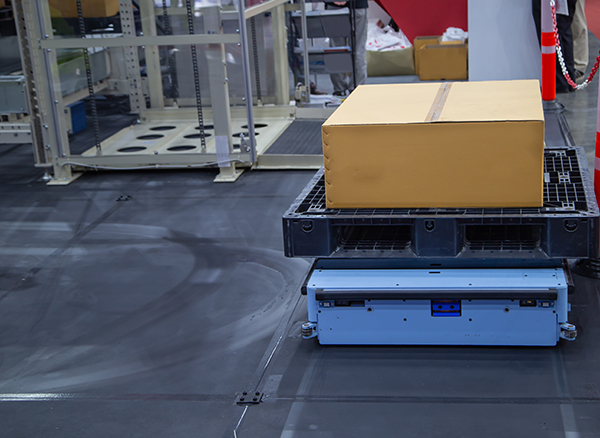

Platform-type AGV

The development of platform-type AGVs has shown great development in recent years. Their range of application is expanding due to the large number of supplementary AGV structures and AGV manipulators that can be built on the parent vehicle. The systematization of autonomous material handling devices ensures the flexibility of processes and their extensibility to serve the horizontal network theory. These devices can also be used for stand-alone and high-performance process services if the operation is controlled by a properly parameterized fleet management AGV server. For this reason, they are also suitable for both warehouse automation as well as production process automation. Although the use of AGV as a stand-alone unit raises production-service issues, with the application of AGV fleet management the units can also be used for milk-run type processes. Thus, the task determines the AGV system’s operation and therefore it is not the tasks that is customized to the AGV system’s automated service processes. Platform AGVs are specifically designed devices, developed primarily for industrial purposes. The size of the automated forklifts is determined by the size of the units to be transported. In terms of their design, the number of variants is almost endless. The bodywork is always an optimally designed component and it is designed for a specific purpose based on plant and process needs.

Platform AGVs are specifically designed devices, developed primarily for industrial purposes. The size of automated forklifts is determined by the size of the units to be transported. In terms of their design, the number of variants is almost endless. The bodywork is always an optimally designed component and it is designated for a specific purpose based on plant and process needs.

The general complexity of tasks requires expert knowledge and consultation as early as in the planning phase. In each case, it is advisable to prepare a multi-stage logistics process plan for each phases. With the experience and support of Zenit Kft., Your automated material handling system and process will be designed and developed in accordance with the relevant expectations, taking into account INDUSTRY 4.0. principles.

AGV with forklift functions

AGVs with forklift functions are widespread versions of the driverless material handling equipment in indoor, and sometimes outdoor areas. The advantage of fork-equipped AGVs is that the unit load is handled independently. In the case of automated forklift no additional material handling equipment is necessary to transport between points A and B. The unit can move loads from the floor, from a rack, or any predefined point, then transport them to the delivery point under the control of the AGV server software. Forklifts can unload independently at delivery points, without the intervention of other material handlers. Their disadvantage to platform AGVs is their robust design and the associated spatial constraints. As the structure’s own dimensions have to be added to the load, it is necessary to calculate with this feature at loading and unloading points, and in the case of turning curves.

Automated vehicles

Automated driverless vehicles are also controlled by the automated material flow control system - MFC. In terms of their design, there are truck-sized and 7,5t truck-sized varieties. The closed cargo space of the bodywork can be refrigerated, air-conditioned, and the platform can even be converted into a conveyor track.