Automated warehouses

When our logistics experts encounter the need of pallet storage, the question arises as to the size, dynamics and complexity of the investment. What is the right and remunerative answer? The possibilities are manifold; outstanding professional experience of Zenit Kft. will greatly support your decision, too. If your company is also in the process of development, and you are looking for an expert team, who review the potential solutions from an objective point of view in the field of warehouse automation, and partial automation, contact us to find the answers for you, together with you, and to even build your future warehouse together!

Let’s see what our options are, when assuming warehouse automation without the need of detailed specification:

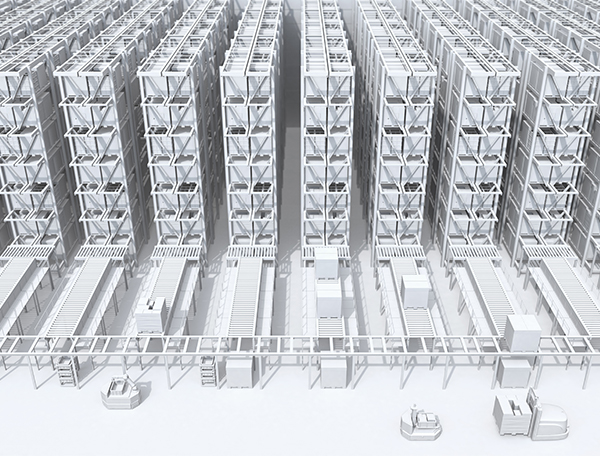

Automated small container warehouse, AKL or mini load

The automated mini load warehouse, with the word used in the industry AKL or mini load, is one of the known type of warehouses. The acronym AKL refers to the German combination of words automatisches kleinteilelager, which by now has become a widely accepted term in logistics.

In more developed economies and warehousing, the form of warehouse automation is widespread, which is a highly dynamic warehouse system with significant space utilization. Optimal choice due to its huge capacity and expandability. In case of mini load automated warehouse, (AKL), the incoming goods to be stored are mostly stored in buffers, from where regulated upload is controlled by a control software. In warehouse racks typically EURO boxes are used, depending on the product types and items to be stored, with standard or different height shelf level layouts. In case of rare products of small size with low turnover speed stored in small quantities, it is possible to share containers, where due to the value of the items or other considerations, secure storage is required. In countless cases, use of custom-made storage containers is necessary due to the products to be stored. Accordingly, layout of the storage spaces and load handling attachment, as well as later material handling can be implemented using individual solutions.

Racks are mostly arranged in single row, on both right and left side of the stacker crane access corridor there is a single-deep rack storage unit. In certain cases, where the variety of items is low, building a double-deep racking can be the optimal solution. Its advantages include the number of storage spaces available at different fields and levels in one access corridor. An additional advantage is that only one stacker crane has to be operated even in case of handling double amount of storage space. A disadvantage is, however, that meeting the FIFO principle and lot batch handling is cumbersome, the inner container can often be removed only after transferring the outer container. In case of double-deep storage, if both containers have to be moved, also the size of the load handling attachment is doubled, thus the size gain calculated along the corridor width is reduced to minimum. A further disadvantage is that the system is not redundant: in case of failure inner container can be accessed only with great deal of difficulty. Double-deep systems are more complicated also in terms of control. Precise determination of the storage space require a great deal of attention, when containers are placed onto racks. Even the smallest error can cause a fatal database crash that can only be overcome with great effort and extra time.

In summary, however, use of the AKL (automatisches kleinteilelager) system results in highly dynamic and precise warehousing process. It is a perfect solution in case of high-speed and high-intensity commissioning that follows the goods to people (G2P) theory, and serves under a principle radically different from that of manual commissioning. A lot of factors have to be taken into consideration for the design of AKL systems, among others the total volume of the goods, the number of items, the planned movement of containers projected for items, dynamics of the system, local warehousing features, the current route and location of the inbound and outbound good, the number of shifts the servicing speed and the peaks experienced there. The design is always a unique and individual process that analyzes the operation of the client, where the current operation broadens the basic knowledge, but does not necessarily forms basis for the subsequent automated operation.

AKL systems are almost in each case supplemented with material handlers, which usually are conveyors, but special solutions can also be introduced At a certain point of the conveyors commissioning points are established, the layout and functions of which may vary depending on the task and the products. Following commissioning, the packaging points, collection points, delivery route sorters can be established. Automated systems are usually controlled by a central controlling software .Its implementation shows a lot of difference. Depending on how well the client’s WMS (Warehouse Management System) software is prepared for the organization and distribution of automation tasks, the later sub-systems will be implemented accordingly.

AKL systems are almost in each case supplemented with material handlers, which usually are conveyors, but special solutions can also be introduced At a certain point of the conveyors commissioning points are established, the layout and functions of which may vary depending on the task and the products. Following commissioning, the packaging points, collection points, delivery route sorters can be established. Automated systems are usually controlled by a central controlling software .Its implementation shows a lot of difference. Depending on how well the client’s WMS (Warehouse Management System) software is prepared for the organization and distribution of automation tasks, the later sub-systems will be implemented accordingly.

It can be stated, however, that the usual layout is the following: ERP-WMS-MFC-PLC.

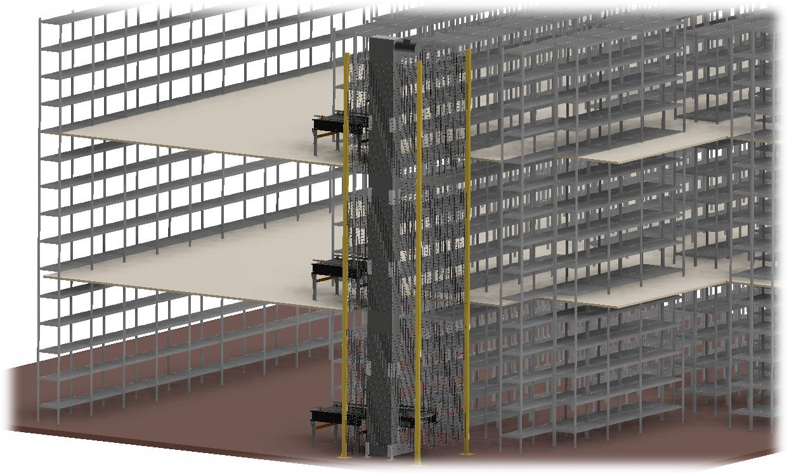

Automated pallet warehouse, APL

Automated pallet warehouse, hereinafter referred to as APL. Regarding its principle of operation it can be identified with AKL. The significant difference is that the unit loads to be stored are typically conventional pallet units. Also the scope of use of the APL is manifold. It can be used as a buffer to fill AKLs, and also for classic pallet storage. Regardless to the purpose of use, the system implementation is similar. The stacker crane introduced with AKL moves in the corridor with a load handling attachment, on both sides of which there are single- or double-deep racks .In case of stacker cranes, due to the mass of the stacks, the structures can be implemented also with two poles, which means that the machine moving longitudinally on the rails in the corridor embraces the stack. This will ensure a more stable driving dynamics, but the total mass of the equipment will significantly increase, so the electric performance and energy consumption calculation for one stack will be considerably different.

It can be said in general that stacker cranes (RGB) operate one machine in each corridor, but in extreme cases, if the turnover rate of the goods does not make it necessary, we also implement automated warehouses in corridor changing layout. As opposed to AKLs, it is not expedient to design APLs in low version; its efficiency is due to its extreme height. When designing investments, it is most often compared to narrow-corridor forklifts, but a 20-30 meters high (deep) APL could not already compete with other “manual” technologies. Regardless to the height of the warehouse, the APL accurately carries out loading and unloading tasks to and from each rack position. Due to the advanced drive management, dynamics of the machines is amazing, the metric considered for the stacker cranes suggests high performance of the loading and unloading double cycle. During the design of APL systems, the maximum possible height and warehouse length should be striven for to reduce cost per stack.

Control of APL systems is similar to that described for AKLs. Loading and unloading pallets, as well as route of the stacks between destinations is managed by MFC control .System integration and a professional company with the adequate knowledge is of vital importance also in this case, as integration to the logistic process and precise cooperation with other automated equipment will bring the desired results only by careful professional hands. APL is hardly ever the only automation in a company process. On the input side, today in many cases stacks are transported to the conveyors by AGVs, or goods coming from production are assembled by palettizer robots, which are then foiled by packaging machines. The same is true for the goods or finished product expediation side, as well. Goods leaving the warehouse can be depalletized by robots and removed from the conveyor to the delivery or further processing space by forklifts. The range of options is quite broad; expectations, needs and fixed processes of the client may significantly affect the layout.

Pallet Shuttle system

The pallet shuttle system is one of the modern solutions for automated warehousing. With respect to its operating principle, tiny stacking machines, “robots” are running horizontally in the warehouse rack. Pallets, bins or other unit loads are migrated to the storage locations one by one. One of the advantages of the system is that enormous dynamics can be achieved, if sufficient number of service robots are deployed. It is also important, how the robots deliver their loads: at delivery points located at the end of the row or at notable points, where lifts migrate them. As a result, the system design is also very diverse.

Efficiency of the system depends on the buyer’s requirements and last but not least the buyer’s wallet. Systems control is similar to the WMS-MFC controlling principle of AKL and APL systems. Introduction of the shuttle technology is hardly ever an independent, island-like project. It is usually part of a logistic process reform or greenfield investment, where its productivity is precisely determined, and so the later supply process is also well-planned.

In most cases standard design shuttle cars are used mostly to handle unit loads, but task-specific individual vehicles are not uncommon, either. In some cases carts are integrated in a more complex design as manipulator carriers and transportation units, where in cooperation with the commissioning robot direct commissioning from rack takes place.

There are 2D and 3D systems. The 2D shuttle runs in a corridor, in FIFO or drive-in racks. Similarly, the 3D system runs in a corridor, however it is a main corridor with sub-corridors and drive-in racks.

During the design and implementation of the systems we follow four material handling and forwarding principles:

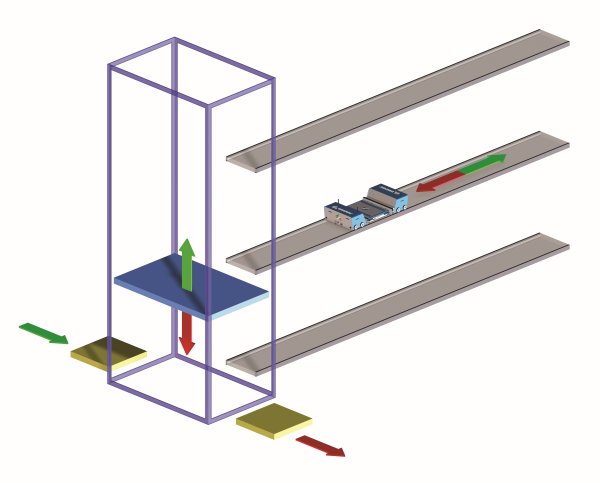

1, the 2D system also operates in semi-automatic system. Carts are lifted to the delivery point of a given level corridor by a forklift. The shuttle brings out the first stack found in the corridor, and/or from here it takes down to the next storage location of the corridor. The pallet is removed from the delivery point by a forklift.

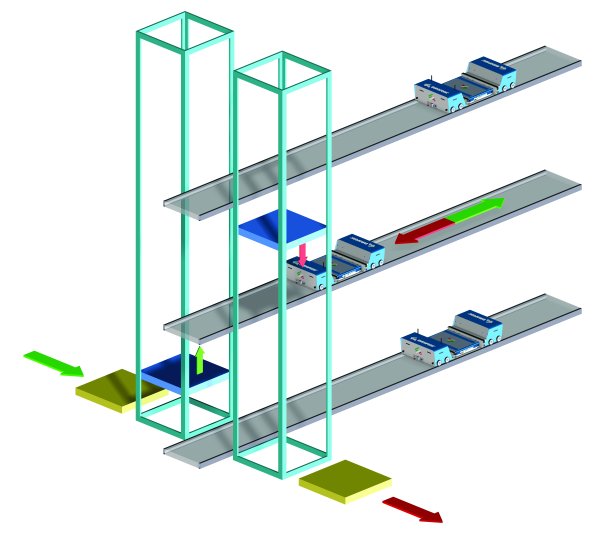

2, The most simple, yet most dynamic solution of 3D systems is the use of one cart for each corridor. In this case, after loading and unloading the stacks, the carts are positioned to the assigned storage location at the end of the main corridor, to the stack migration lift, loading from and unloading to that location. Stacking elevators migrate the goods between the corridors and the conveyor of the material flow system.

3, If storage capacity is important, but no priority is given to the dynamics of unloading and loading, we recommend the corridor shift solution of 3D systems, using one or two carts. Carts are repositioned between the corridors by the central shuttle migrating elevator. The cart drives on the elevator, which lifts and repositions it to the adequate main corridor, from where the equipment unloads and loads according to the command. In this case, too, the carts - after unloading and loading stacks to the assigned storage locations, are positioned to the stacking elevator located at the end of the main corridor, and take/deliver stacks from/to the elevators from the integrated material handling systems.

4, If storage capacity is important, but the dynamics of unloading and loading is rather low, we recommend the corridor shift cart migration solution, using one or two carts. Carts are repositioned between the corridors by the central shuttle migrating elevator. The cart drives on the elevator, which lifts and repositions it to the adequate main corridor, from where the equipment unloads and loads according to the command. After unloading and loading the stacks to the assigned storage location, the carts return to the shuttle elevator. The elevator migrates them to the stack delivery point. From here, they are migrated to the elevators by integrated conveyor systems.

Elevator, paternoster elevator, carousel

Putting it simply, vertical material handlers are lifts, equipment to migrate unit loads vertically. With respect to their operating principles, they can be divided to two main classes:

Continuously operated vertical material handlers (S-elevator, spiral conveyor, etc.)

In case of continuous vertical material handlers, the vertical material handling performance is higher, as the lifting per elements are implemented as a single material flow chain, and this allows uninterrupted product flow.

This solution has a number of advantages compared to the conventional industrial elevators, because the material handling platform of the system is in continuous movement. On the other hand, classic vertical material handlers have only one lifting surface that transports the goods between 2 or more points with intermittent control, and is stopped during each loading/unloading cycle.

Due to their compact design, these material handling systems require very little floor space. Compared to chutes, their built in floor area is low, and can be run both upwards and downwards. Sloping are similarly capable of handle material to both directions in a much smaller space.

Intermittent elevators

Systems known as classic elevators can be interpreted as systems of intermittent operation. The migrate between locations A and B autonomously, responding to a starting signal. the need controlling also to map their own movement. The least complex designs are prepared for movement between two points, but with thoroughly designed control and adequate construction, the machine are naturally suitable for movement with multiple loading/unloading points within their area of movement. Drives are scaled taking into account the mass of the stack to be migrated and the expected cycle times, and as a result of the scaling, once the lifting engines and propulsion units are determined, the lifting speed and acceleration can be calculated.

In the light of these values, as well as taking into consideration the idle times per cycle, the process of operation can be precisely described, which can be used as a stable basis for system planning. Exact calculation of the lifting cycles is very important in case of fixed-track systems, because these are the points that interrupt the so far continuous operation of the conveyor system.

In addition to solutions integrated into the conveyor system, for the sake of room optimization - besides adequately reallocating resources - Zenit Kft. also offers complete warehouse reconstruction solutions, which - in addition to building static equipment - contain automated equipment, as well, thus ensuring efficient working.

Paternoster lift, vertical elevator, carousel

One group of automated warehousing is storage on trays. Paternoster and vertical elevator have similar design, but different operating principle. The equipment store trays under an outer shell on different levels, different density, size and load bearing capacity. The product is usually requested by the operator, which is performed by the automated warehouse autonomously by migrating the corresponding storage tray to the operator. A basic difference in the operation of lifts and paternosters is that the latter circulates the trays along a vertical axis, whereas the moving mechanism of the vertical storage lift unloads/loads the product carriers stored on the two vertical sides.

Use of paternosters has a long history. Initially, they were used to store documents and passenger traffic instead of the cyclic elevators.

Later, with the rise of industrial automation, the field of their application has become much broader. Today, offering a broad range of options, manufacturers aim to create the illusion of a fully automated warehousing system for users. But most of the standard designs operated on semi-automatic principle. This means that the users need some kind of information on the product to find it in the system.

Another large group belonging to this branch is that of vertical elevators, which beat the operating principle of the paternoster in terms of efficiency, but rely on similar basis regarding the warehousing system. They are widely used, and can be found in numerous logistic tasks from small parts to high volume of metallic stick storage automated warehouses.

The third group is the horizontal carousels. This type is less common in Hungary. Unlike automation solutions mentioned earlier it is competitive on the investment side. It can be useful in low-built warehouses, where horizontal space utilization is more typical. In case of certain product types, where typically vertical or overhead storage is possible, for example in automated clothing warehouses, it is an excellent solution for warehouse automation. Its disadvantage is slower access to the products in case of serial systems. But with simultaneous use of multiple horizontal carousels, efficiency per worker can be significantly improved. Due to lower energy consumption of horizontal migration, maintenance and operating costs are lower. As it is a block storage type form of warehousing, in comparison with classic warehouses, the storage area can be reduced by 40-60%.In modern systems there are independent storage routes moving even on multiple levels, which considerable increases the intensity of commissioning.